Hot crimping

Direct connection of wires and enameled wires with cable brackets by means of resistance weldingHot crimping – reliable connections between wires and enameled wires without prior stripping

We have introduced a new technology that enables the joining of enameled wires without prior stripping. This process is based on our general resistance welding process, which has been a proven method in automotive, medical and solar technology since 1984.

In order to create a reliable and high-quality welded joint according to your specifications, the welding heads or guns of our resistance welding machines have a special mechanical design. Each model is calculated and designed specifically for your application using FEM software. Our machines generate the required welding pressure and transfer the strong welding current in a very short time.

Vaporizing as an alternative to stripping

Due to these properties in combination with intelligent power sources, our machines can vaporize the insulation of each individual enameled wire without affecting the copper. The insulation vapors are removed by an extraction system. During the entire process, our PC-based welding controllers enable precise monitoring.

What is hot crimping and which wires is it suitable for?

Hot crimping is a welding process based on our resistance welding process for non-ferrous metals such as copper. It is suitable for enameled wires (e. g. for motor, stator and generator production, medical applications), insulated HF strands (e. g. for transformers and chargers) or conventional copper wires (highly flexible, regularly stranded or braided strands, e. g. for electric or hybrid vehicles).

We can process all wire types as single strands from a cross-section of 0.05 mm² or as stranded or braided bundles up to 400 mm². The thickness of the individual wires is irrelevant, meaning that HF cables can also be crimped. In addition, all conventional wires with different coatings (e. g. silver, tin or nickel) can be used. As a result, this process is also suitable for high-temperature applications. The plugs and sleeves used can be made of bare, tin-plated, nickel-plated or silver-plated copper.

What applications is hot crimping suitable for?

In the past, connecting enameled wires with each other or with cable brackets were extremely time-consuming and expensive. This was due to the manual effort required to remove the enamel layer from each individual wire. If a wire bundle had to be welded, it was almost impossible to strip it in a single step. An employee had to heat the wires with a flame and connect the wire bundle manually by feeding in braze (in the form of a rod). This process took time and did not work reliably. Today, we can weld these wires to a terminal or sleeve without having to strip the insulation first. This is because the insulation is vaporized during resistance welding and the wires are joined together.

This procedure has the following advantages:

- None of the test methods used in the automotive and medical industries detected any aging of the welded joints during their entire service life.

- There is no more crimped connection that could loosen or relax over the course of its service life.

- This procedure is safe because all necessary parameters are monitored.

- It results in a particularly high conductivity without voltage drops due to the low contact resistance.

- Due to the high tensile strength (high tensile forces) of the individual wires, there is no slip effect when pulling.

- The connection is vibration-proof and temperature-resistant.

- Furthermore, the connection is resistant to environmental influences.

- The process can be fully automated.

What are the differences between hotcrimping and traditional crimping?

Conventional crimping creates a mechanical connection that can come loose during the service life of the product due to ageing (relaxation of materials). In contrast, with hot crimping, the materials are fused together by resistance welding without stressing the copper. This creates a connection between the joining partners that has virtually no contact resistance and does not age during its service life. Due to the perfect resistance and the intermetallic connection, no oxidation occurs, which would increase the resistance during use of the product.

Even for high-current applications with large cross-sections, this technology achieves safe and reliable connections that function without failure even after the required power supply cycles. In addition, the mechanical tensile forces are particularly high and stable, as sleeves and wires are joined together. Our PC welding controllers also allow for monitoring of the process parameters. This also includes data tracking in a database or marking the product for complete traceability, as required in automotive, medical and solar technology.

How does hot crimping work?

Resistance creates an intermetallic connection between the individual wires. Specially designed welding heads generate the necessary welding force on the cable bracket or sleeve. They also transfer the welding current to the joining partners within a very short time without stressing the copper. As an option, this process can be monitored and controlled using our intelligent power sources and PC-based control systems. In specially programmed pulses, the welding current generates the required temperature to vaporize the insulation and to weld the wires together. This creates an alloy between the wires and the sleeve or cable bracket that forms a perfect electrical connection between the individual wires. The required mechanical tensile forces of each wire in the bundle are also achieved without slip effects.

Which parameters are essential for the hot crimping process?

Three key parameters are important for producing a welded joint: welding current, welding time and welding pressure. If you wish to avoid dealing with these parameters in depth during operating, our PC systems can preset default values. In this case, only any necessary fine adjustments need to be made manually. The default values represent our recommendations, which have been set according to the relevant application. Alternatively, the operator can use freely programmable profiles.

What kind of equipment is needed for hot crimping?

To cover the entire spectrum of customer requirements, we produce and supply turnkey systems ranging from table-top units to fully automated production lines. These machines process the products in sequence to enable different crimp sizes or product combinations. Our machines can be designed as a module or with a welding head or gun to suit your available floor space. Please send us a sample for a detailed quotation on the appropriate equipment.

Machines

(customer-specific solutions as an example)

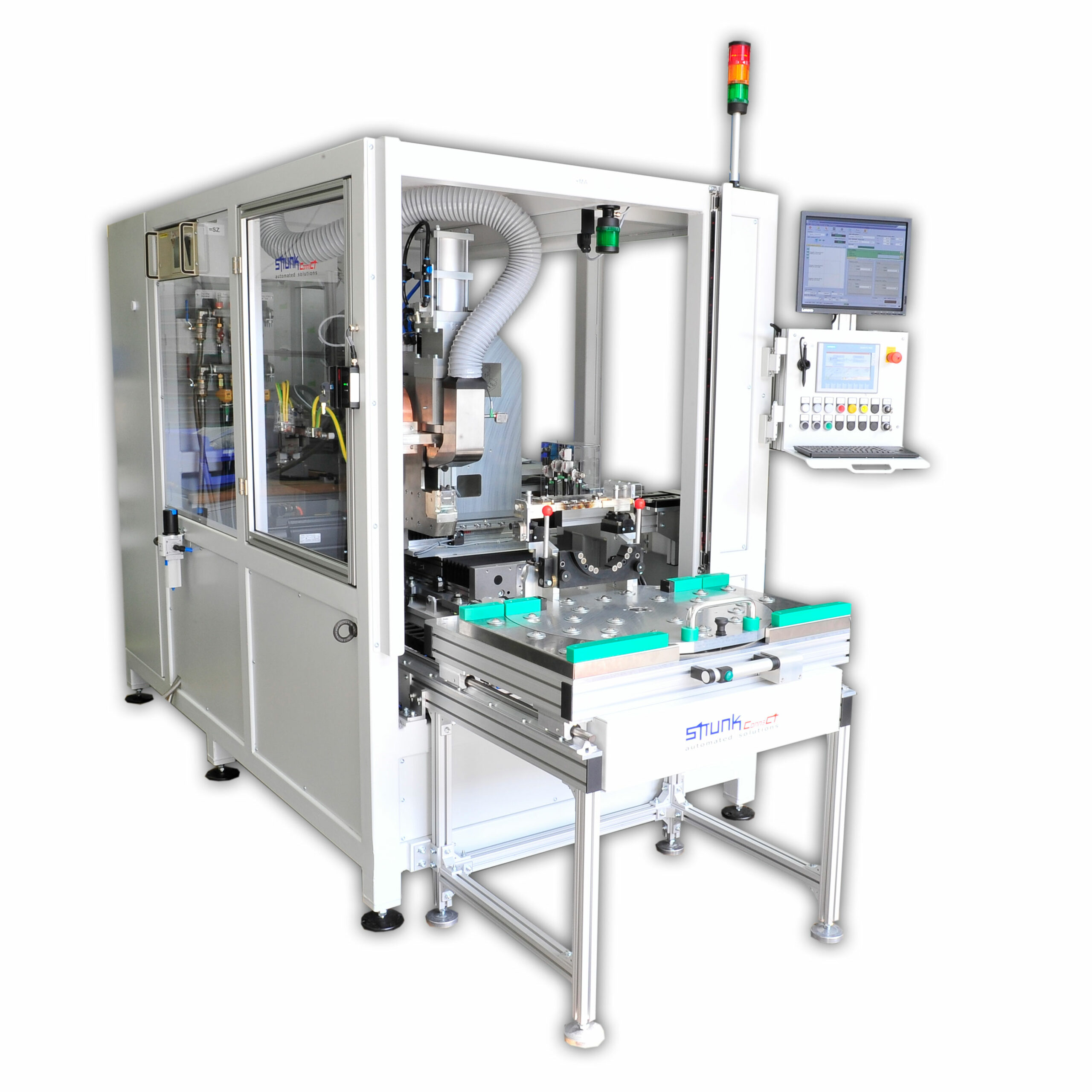

Fully automatic tong welding system with 150 kVA and transfer belt for hot crimping phase connections and star points of geared motors

This machine is designed for upright stators on tool carrier systems. It contains a STRUNK servo rotary lifting unit and a portal system with servo feed in the x, y and z directions. This four-axis machine can therefore reach and process all positions on a pallet.

Fully automatic welding system for hot crimping with a rotary lifting table mechanism

This welding cell has an S-MMD2 or S-MMD3 module for hot crimping connections of sleeves and ring or tubular cable brackets for geared motors in the BEV or HEV sector. All components are presented via a WT, which is fed into the machine by a WT belt system and returned to the WT belt system after the entire component has been processed.

Semi-automatic welding cell for hot crimping stators incl. interchangeable tool carriers for different sizes and designs

This system is designed as a welding tong machine on x, y and z servo axes with 150 kVA AC. Its transformer and secondary are permanently connected so that the secondary paths can be kept extremely short. This enables high outputs and therefore the welding of large cross-sections in the shortest possible time. Via a front side WT system, the stators are rotated by 180° and fed into the machine. Once all connections have been welded, the tool carrier is unlocked and made available to the WT system for removal.

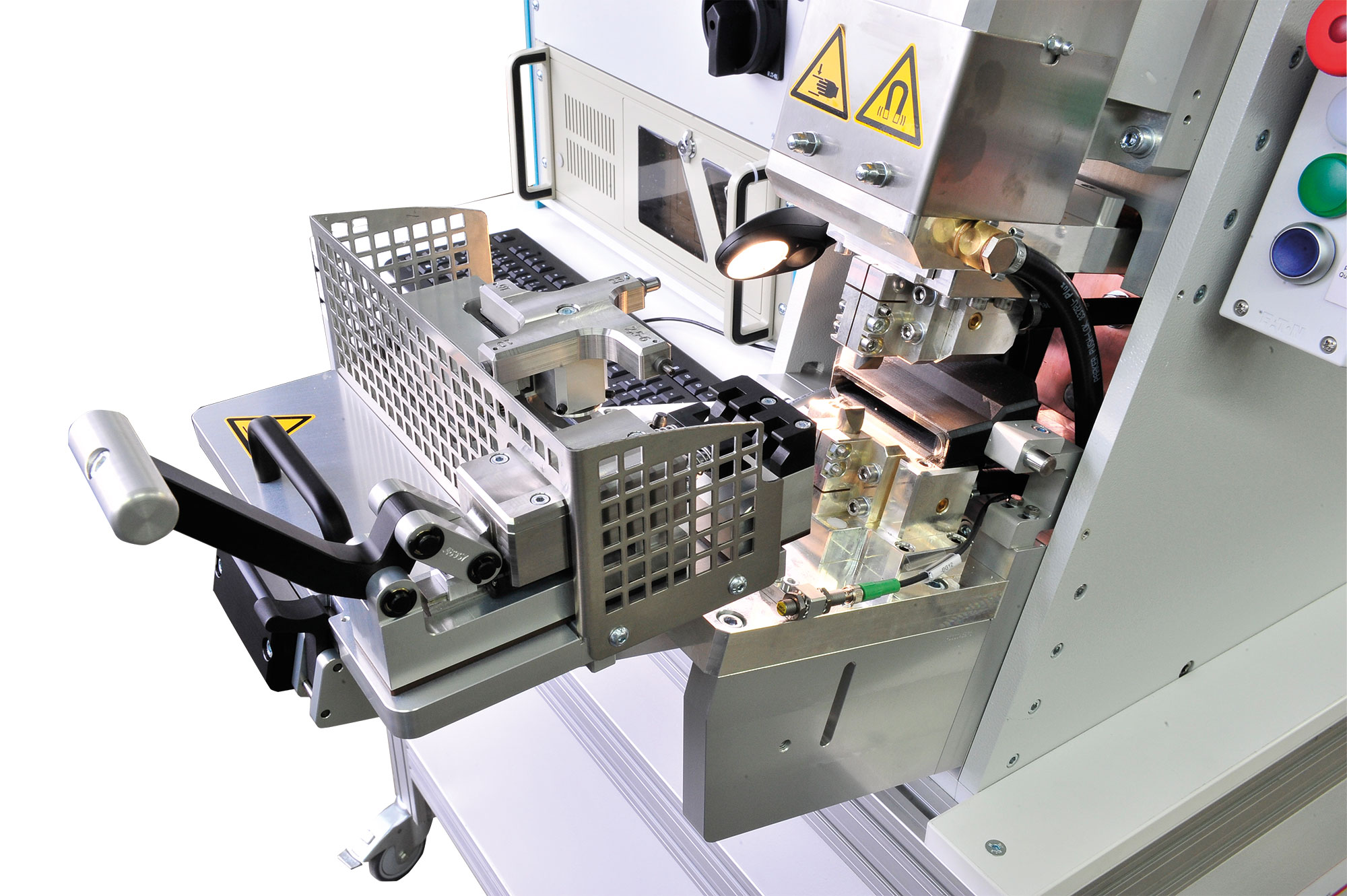

S-MMD1 for hot crimping of stators

This S-MMD1 system can be supplied as a manual workstation or as a module for assembly. It features a drawer system guard and a left-aligned welding tool for short tap lengths. The module is particularly suitable for stators for standard motors with diameters between 63 and 225 mm. Usable connection parts are ring terminals, tubular cable brackets or sleeves. For different contact parts, special rotatable holders are provided, which in turn can be changed quickly. Therefore, end and feed-through connectors can be produced.

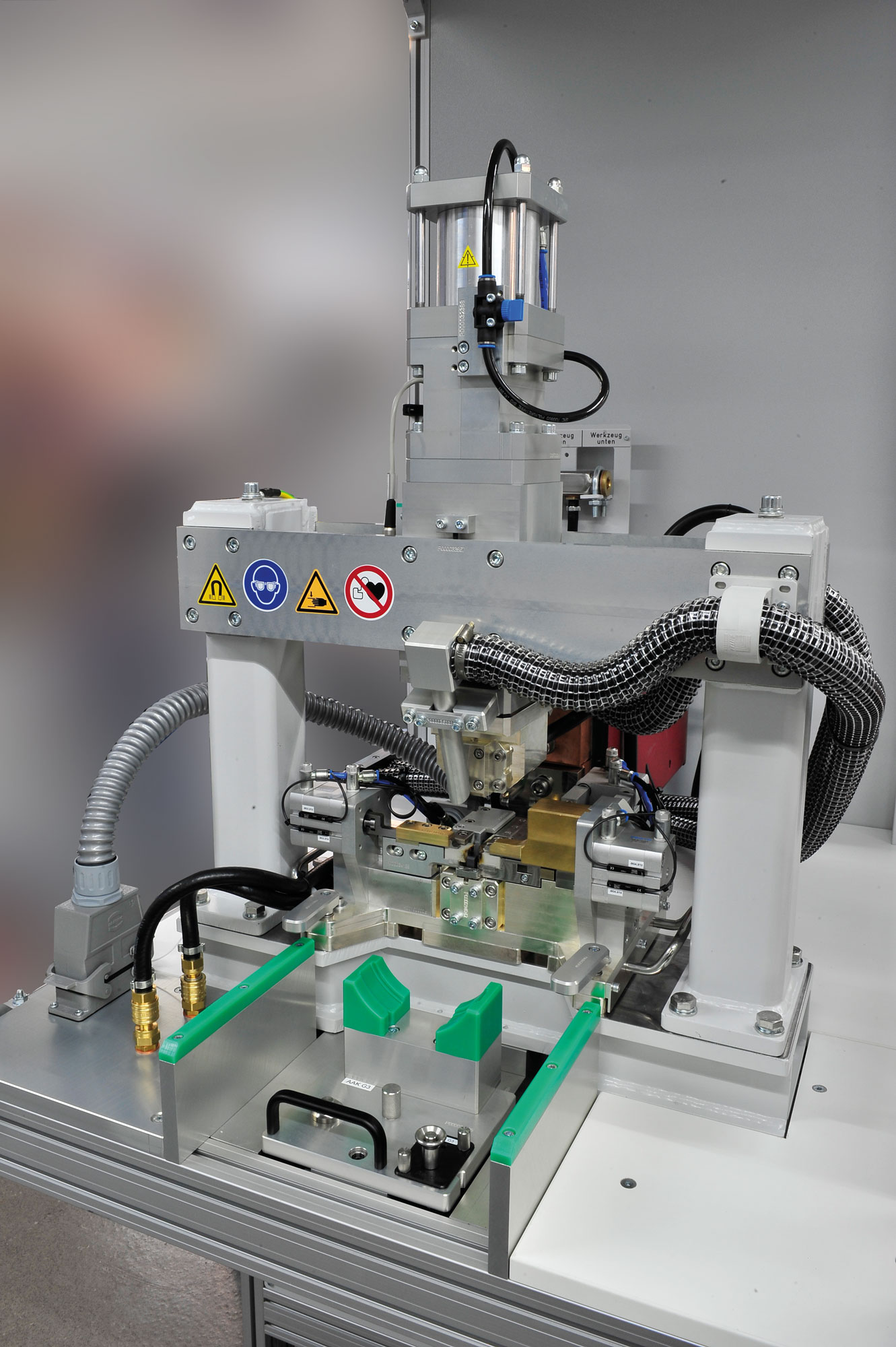

S-MMD3 for hot crimping applications

This S-MMD3 system is available as a module and for table integration. It has a left-aligned table structure and a tool structure for on-site feed of lifting scissor tables or transfer belts for fixing or feeding stators. For different contact parts, special rotatable holders are provided, which in turn can be changed quickly. Therefore, end and feed-through connectors can be produced. Optional gripper systems allow for the fixation of cable bundles without damaging the insulation. The spring grippers can securely hold a large cross-sectional range of cable bundles.

Strip welding system for processing by hot crimping

This manual STRUNK welding tong machine is designed as a strip welding system with servo feed of a punched copper strip to a bending unit. The copper strip is bent into a crimp geometry so that the outlets of the stators can be manually inserted into the crimp. The welding (hot crimping) between ceramics is then carried out automatically. Even with varying filling levels, the special ceramic tool ensures that a defined width is reliably maintained. Sequential production is also possible with this device.

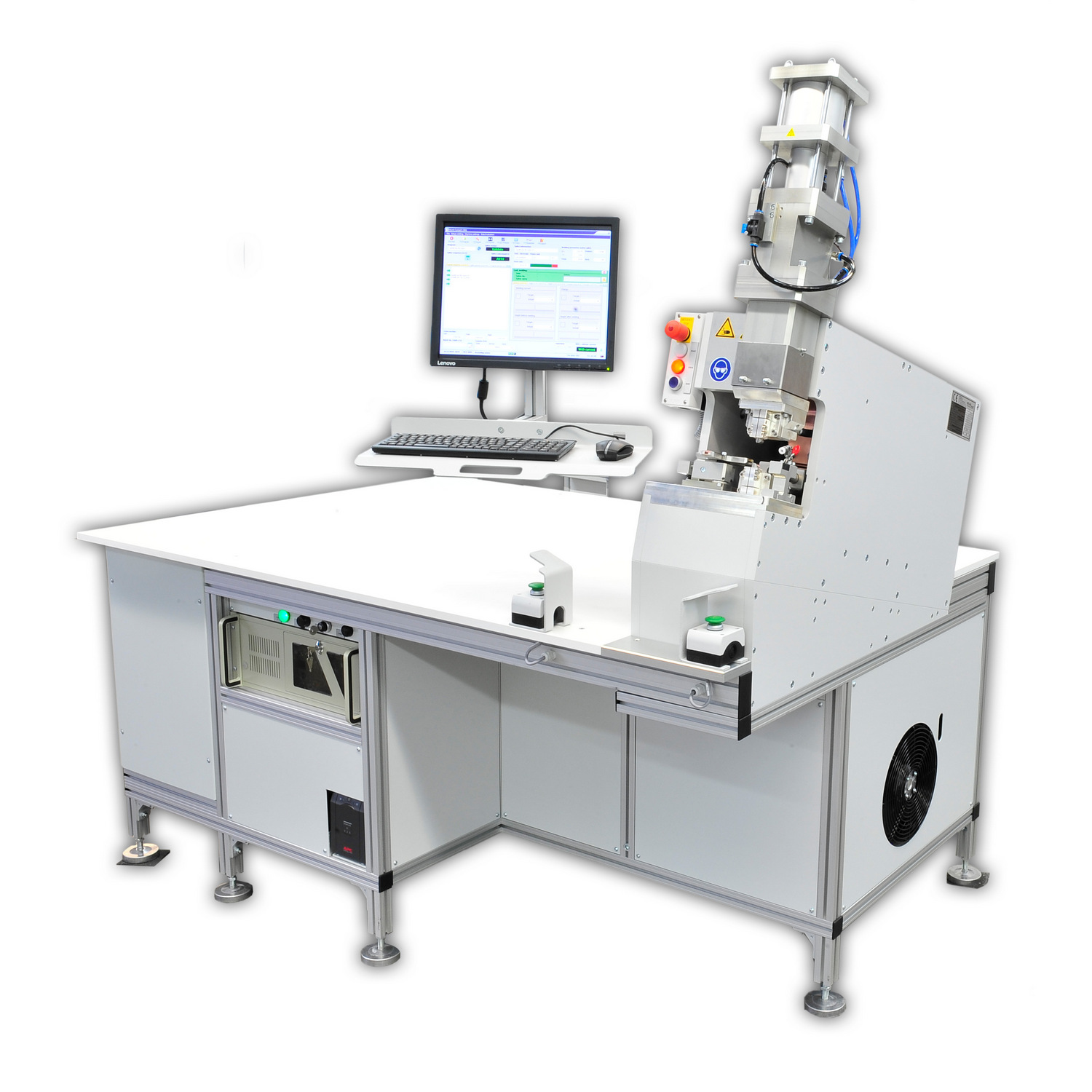

Manual welding system for high cross-sectional areas

This manual tong welding system with 200 kVA AC is designed as a flat bed machine. Its transformer and secondary are permanently connected so that the secondary paths can be kept extremely short. This enables high outputs and therefore the welding of cross-sections between 25 mm² and 300 mm². The stators are presented on the right-hand side of the system via a conveyor belt or a lifting table. Thanks to the compact tool geometry, the shortest possible cable lengths can be processed even with large cross-sections.

Semi-automatic tong welding system for hot crimping with rotary lift table mechanism

This system is designed as welding tongs on x, y and z servo axes with 150 kVA AC. Its transformer and secondary are permanently connected so that the secondary paths can be kept extremely short. This enables high outputs and therefore the welding of large cross-sections in the shortest possible time. The stators are manually pushed onto the STRUNK HUBFIX servo rotary unit at the front via a WT system. After the safety gate is closed, the stator is processed automatically. Once the routine has been processed, the WT is ejected manually by pushing it on a roller conveyor.

Portal welding system for hot crimping of stators

Thanks to the free tool access, this portal system enables the processing of very short cable and tap lengths. All tools for different applications can be changed quickly. Poka Yoke is enabled via monitored storage and our tool management system “STRUNK Tool Management”.

Samples

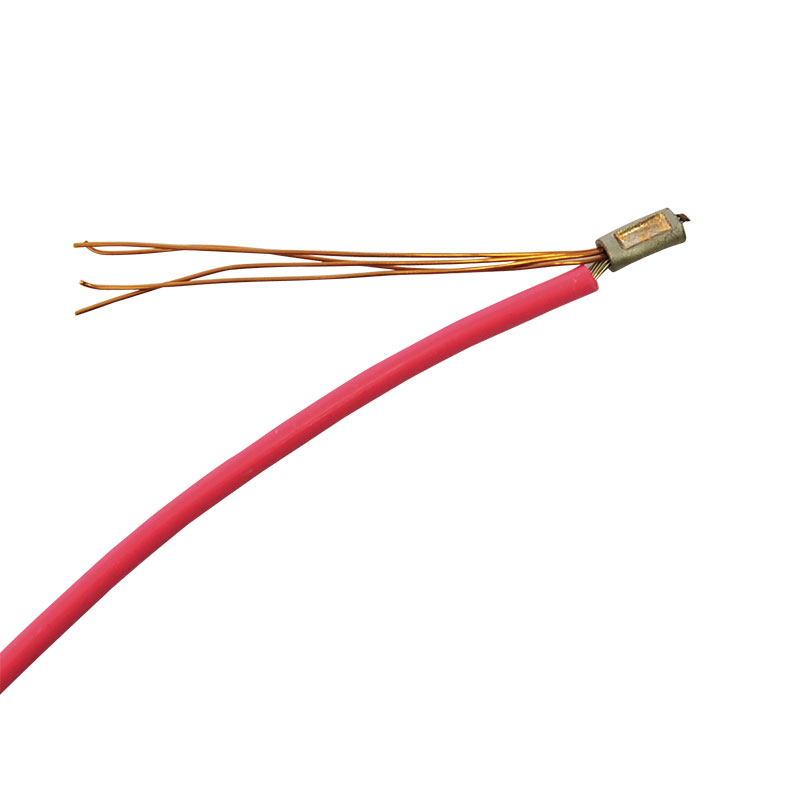

HV, bare copper, to ring cable bracket, silver-plated

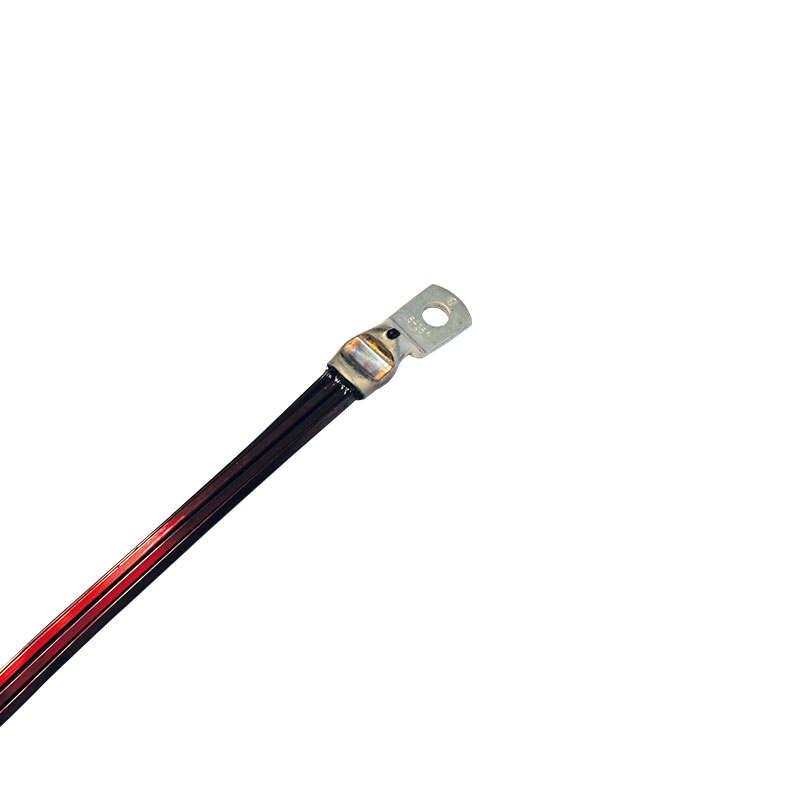

Charging plug for EVs incl. charging socket, standardized according to processing guideline

Charging plugs for EVs and hybrid vehicles

Charging plug for EVs incl. charging socket, standardized according to processing guideline

Enameled copper wire or mixed connection with supplied punched strip

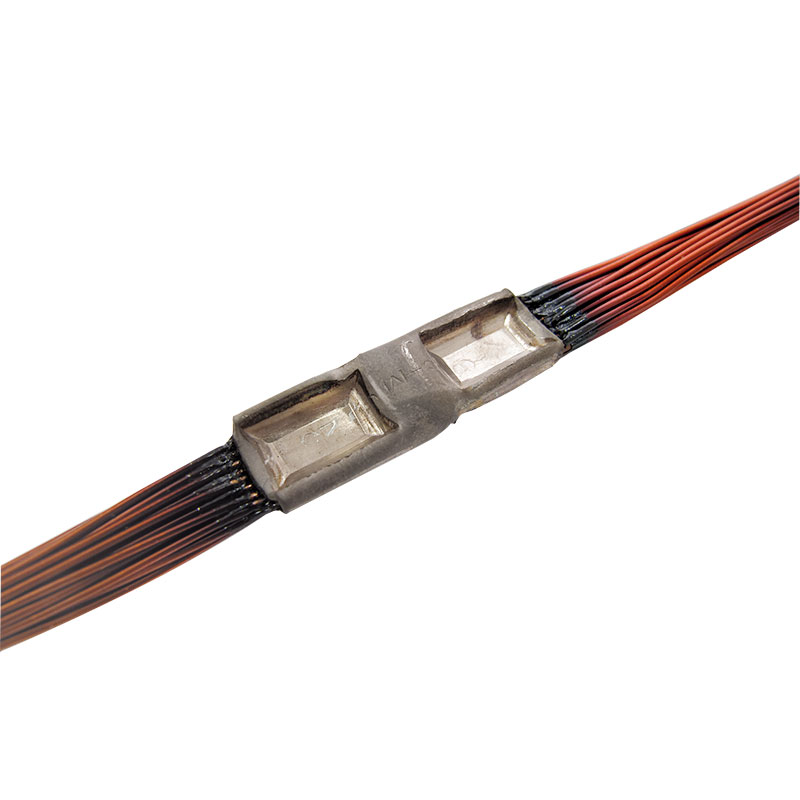

Two opposing connection welds of a flat braid to contact material, made with a special seesaw tool

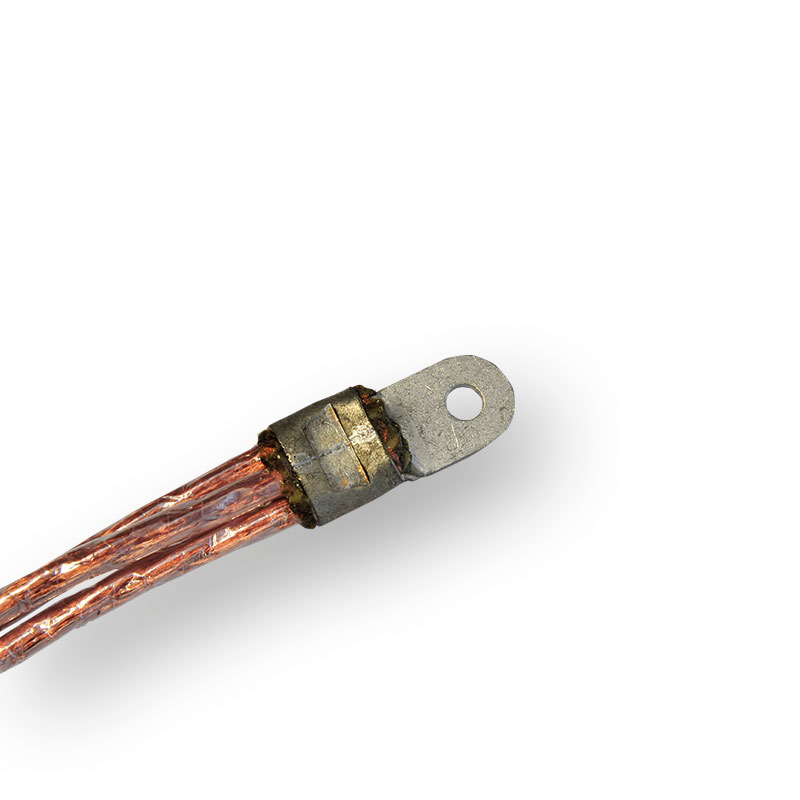

Enameled copper wire to cable bracket, bare copper

This is an example of a connection of profile enameled wires to a silver-plated cable bracket.