Micro welding/Small part welding

maximum precision for the smallest componentsMicro welding – maximum precision for the smallest components

In industries such as automotive electrics/electronics, medical technology, microsystems technology and electronics, the size of components is constantly decreasing. Complex solutions are required to reliably connect these tiny parts electrically and mechanically. These can often only be achieved by means of automated production.

In order to securely join very small parts, low amounts of energy must be applied precisely. Welding times must also be kept as short as possible. We use power sources with frequencies of 1000 to 30,000 Hz for this purpose. Sensitive electrode drives ensure that the welding energy is reproducibly applied to the components with pinpoint accuracy. Monitoring, quality assurance and data storage are carried out in-line using our monitoring systems.

Of course, we also design and manufacture our micro welding systems individually, according to your requirements. The micro welding applications are typically used within a component (e. g. busbar, electronics or sensors) and for its connection to a cabling system.

Our service for micro welding applications

We offer a consulting service to implement automation throughout the entire work-flow (in terms of installation spaces, alloys, surfaces (coatings), accessibility, components to be used, compositions and injection molding installation spaces). Thus, we enable you to produce the desired components in series with process reliability.

Micro welding applications are equally suitable for joining cables and parts (component production). With the latter, lead frames can be connected to each other or to other components.

In addition to C-module technology and portals, we manufacture welding tongs for these applications according to your requirements. Our range also includes integrating them into the application. Different drive systems and motion profiles can be used.

Our vertical integration ranges from sampling to mechanical and electrical design as well as programming with our own mechanical production, mechanical and electrical assembly. This enables us to react flexibly to your wishes and specifications. In this way, we offer you comprehensive solutions from a single source.

You too can benefit from our expertise in micro welding. Use this potential to increase efficiency and intelligence of your production processes. Please contact us for more information.

Maschinen

Micro welding system (MSK) for welding small parts

This micro spot welding system (MSK) is designed for welding small parts. In addition to component welds, stranded wires below 0.35 mm² can be joined with terminals or wires of other alloys. The system is available with a flush tool set to be able to process very short tap lengths of wire ends.

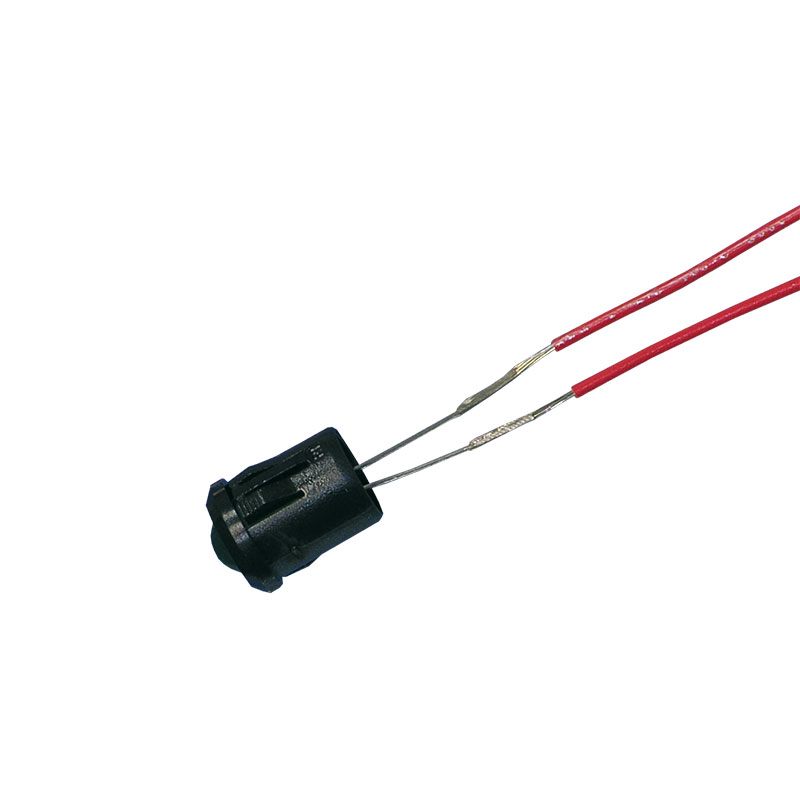

This micro welding system can be used for NTC connections or he welding of Hall sensors on twin cables, for example.

This machine is available as a manual workstation. Alternatively, it can be supplied integrated into a semi-automatic system with interchangeable tools and quick-change couplings with a built-in multi-spot welding tool and driven ceramics.

Samples

Tin-plated cables to NTC

Anwendung von Profillackdrähten zu Kabelschuh, versilbert als Handarbeitsplatz. Das Portalsystem ermöglicht durch den freien Werkzeugzugang die Verarbeitung von sehr kurzen Leitungs-/Abgriffslängen. Die Werkzeuge für unterschiedliche Anwendungen sind schnellwechselbar. Poka Yoke wird über überwachte Ablagen und unsere Werkzeugverwaltung “STRUNK Tool Mangement” realisiert.

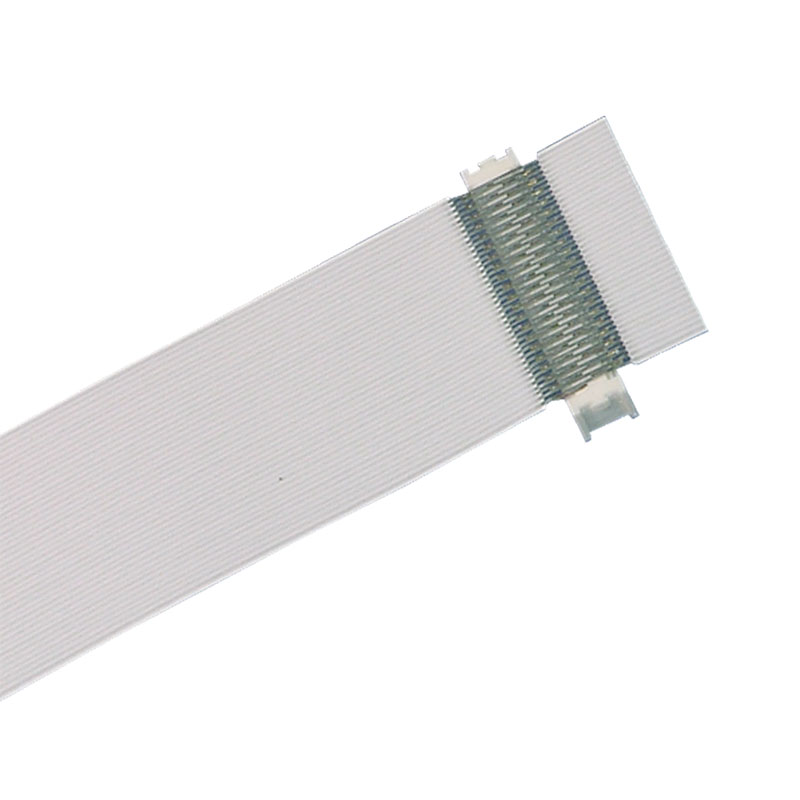

FFC to terminal

Anwendung von Profillackdrähten zu Kabelschuh, versilbert als Handarbeitsplatz. Das Portalsystem ermöglicht durch den freien Werkzeugzugang die Verarbeitung von sehr kurzen Leitungs-/Abgriffslängen. Die Werkzeuge für unterschiedliche Anwendungen sind schnellwechselbar. Poka Yoke wird über überwachte Ablagen und unsere Werkzeugverwaltung “STRUNK Tool Mangement” realisiert.

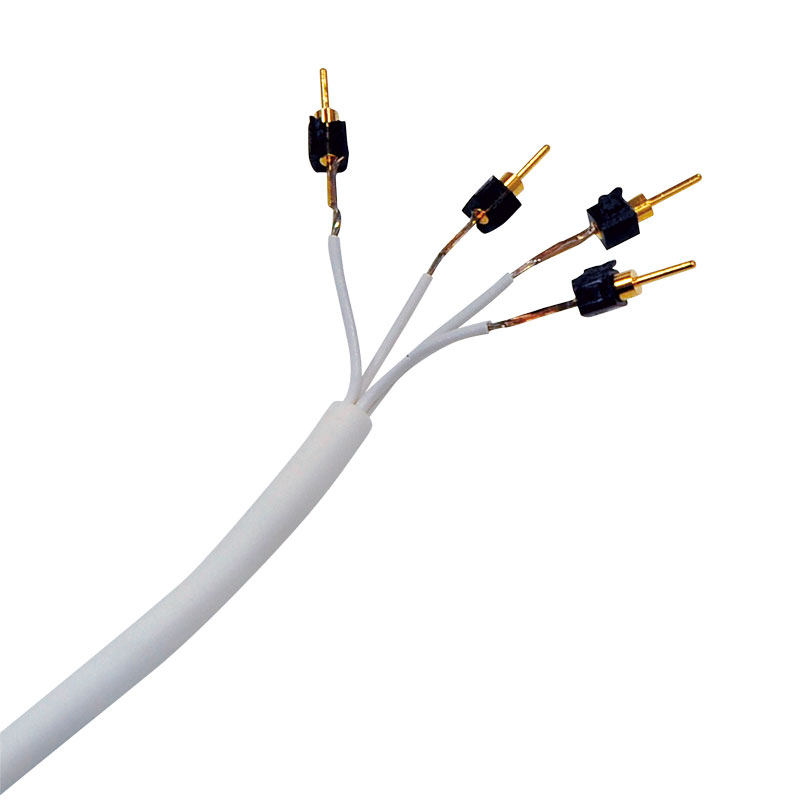

Resistor to LED and cable

Anwendung von Profillackdrähten zu Kabelschuh, versilbert als Handarbeitsplatz. Das Portalsystem ermöglicht durch den freien Werkzeugzugang die Verarbeitung von sehr kurzen Leitungs-/Abgriffslängen. Die Werkzeuge für unterschiedliche Anwendungen sind schnellwechselbar. Poka Yoke wird über überwachte Ablagen und unsere Werkzeugverwaltung “STRUNK Tool Mangement” realisiert.

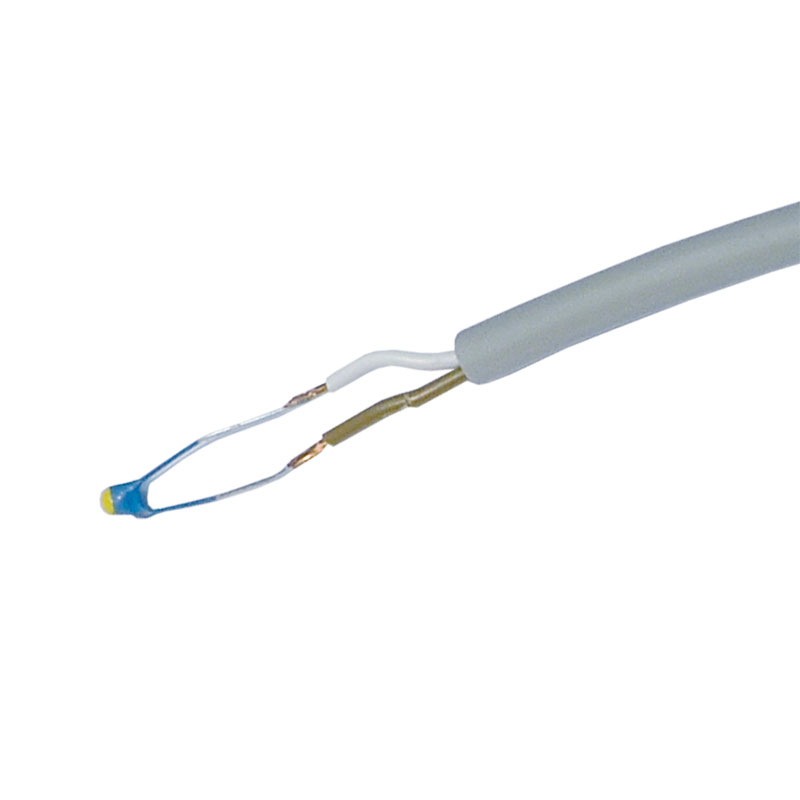

Sensor to sheathed cables or twisted pair wires

Anwendung von Profillackdrähten zu Kabelschuh, versilbert als Handarbeitsplatz. Das Portalsystem ermöglicht durch den freien Werkzeugzugang die Verarbeitung von sehr kurzen Leitungs-/Abgriffslängen. Die Werkzeuge für unterschiedliche Anwendungen sind schnellwechselbar. Poka Yoke wird über überwachte Ablagen und unsere Werkzeugverwaltung “STRUNK Tool Mangement” realisiert.

Capacitors and Hall sensors to lead frames

Anwendung von Profillackdrähten zu Kabelschuh, versilbert als Handarbeitsplatz. Das Portalsystem ermöglicht durch den freien Werkzeugzugang die Verarbeitung von sehr kurzen Leitungs-/Abgriffslängen. Die Werkzeuge für unterschiedliche Anwendungen sind schnellwechselbar. Poka Yoke wird über überwachte Ablagen und unsere Werkzeugverwaltung “STRUNK Tool Mangement” realisiert.

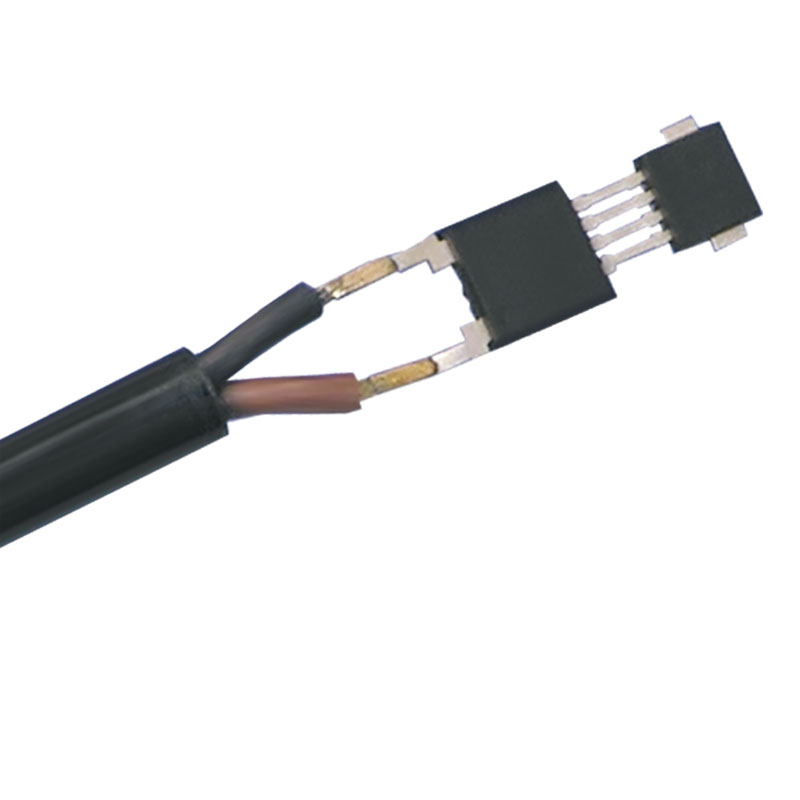

Sheathed multi-cable to micro connector system

Anwendung von Profillackdrähten zu Kabelschuh, versilbert als Handarbeitsplatz. Das Portalsystem ermöglicht durch den freien Werkzeugzugang die Verarbeitung von sehr kurzen Leitungs-/Abgriffslängen. Die Werkzeuge für unterschiedliche Anwendungen sind schnellwechselbar. Poka Yoke wird über überwachte Ablagen und unsere Werkzeugverwaltung “STRUNK Tool Mangement” realisiert.

SCR cables

Welding of cables to heating wires and resistors, can be realized with manual workstations and automatic modules

Capacitors to leadframes on substrate

Welding of cables to heating wires and resistors, can be realized with manual workstations and automatic modules

Capacitor and LED to lead frame

Welding of cables to heating wires and resistors, can be realized with manual workstations and automatic modules

Filter systems for e-mobility

Welding of cables to heating wires and resistors, can be realized with manual workstations and automatic modules

Filter systems for e-mobility

Welding of cables to heating wires and resistors, can be realized with manual workstations and automatic modules

Sheathed cables 0.5 mm² to connector system

Welding of cables to heating wires and resistors, can be realized with manual workstations and automatic modules

Sheathed cable 0.5 mm² to ignition pill for airbag systems

Flat ribbon to plug, created with a beam welding system

Braid to coil and triggering element of a fuse

Flat ribbon to plug, created with a beam welding system